Since my previous Substack post, I’ve been busy getting started on making the first prototype backplane parts. My Ender-3 and a workbench were retrieved from storage, a space was cleared for it, the printer was cleaned up and I ensured it was in working order, then I’ve got to work printing out some simple test prints of a single backplane block and supports.

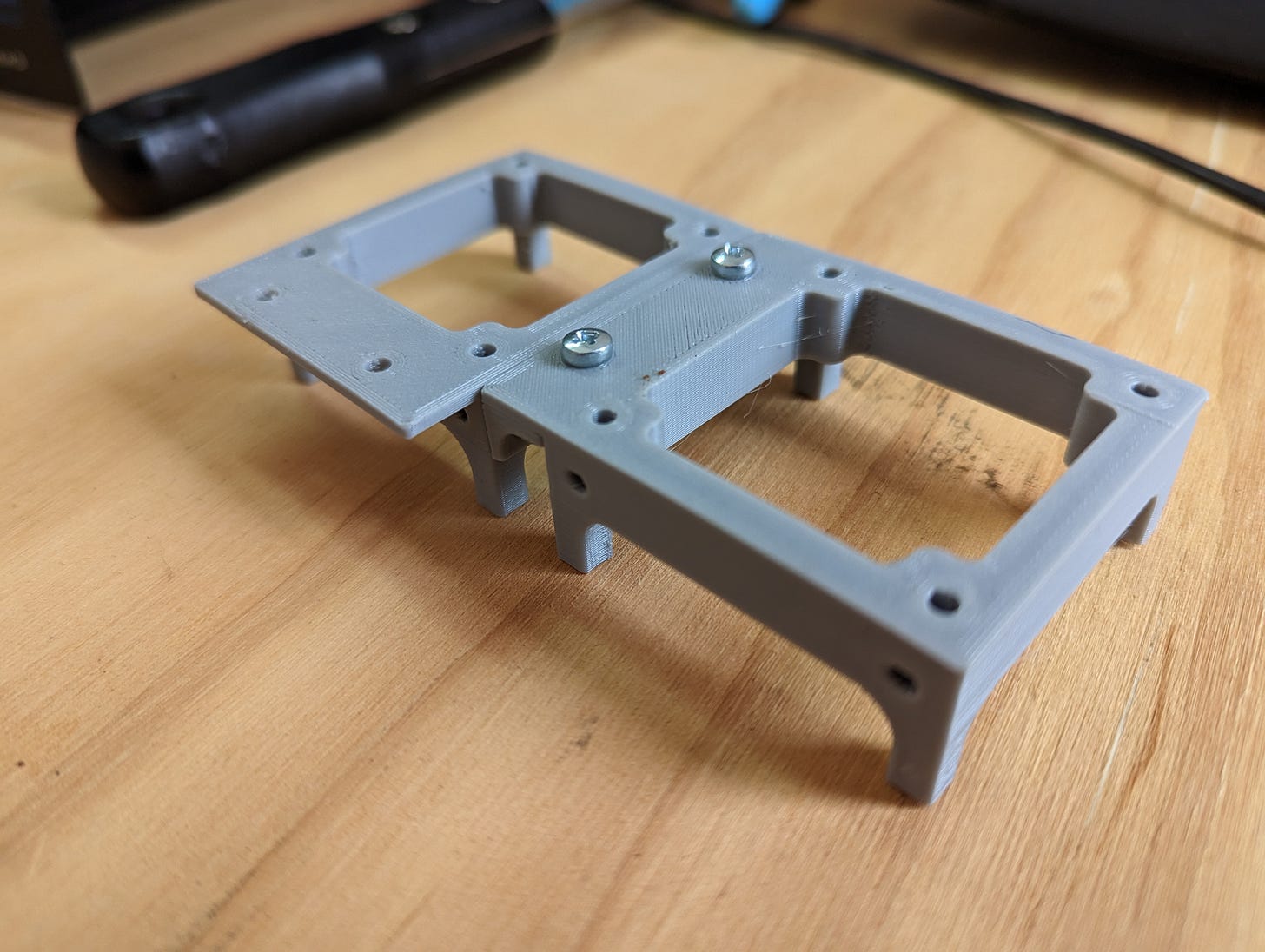

I started with a print in PLA filament, which turned out reasonably well at first glance but quickly showed its deficits when I printed a support and a second block, then screwed them together. The pieces went together just fine, but screwing the support into the side of the block showed the weakness of the material. PLA is a bit brittle, and the layers started to crack at the screw holes on the side where screws were attached.

I have one spool of PETG, and decided that would be worth trying in place of PLA. Turns out that was probably a good choice. My next prints in PETG, while not perfect, showed much better properties for use as a mechanical material. The pieces are definitely not as brittle and the layers haven’t tried to separate when screwing into the side. The screw threads seem to bite into the material much better as well.

Those of you who use FDM 3D printers know that dialing in the settings for a new filament type can be a long process. After a few false starts, I’ve got a decent, but not perfect, set of parameters for printing PETG. I’ve got some bed warping and a bit of stringing to eliminate yet. It does seem a bit more finicky than PLA, so I’ll probably be working on this for a few more days.

Soon, I’ll start printing full sections of the backplane, which are going to take significant amounts of time to print. Assuming I get the tuning down, I won’t have to do much babysitting of the prints, and I can start on the power supply schematics and PCB. I’ll have another update for you when I have a fully-printed backplane to show off!