Spring Fever

The outdoors beckon

As Project Yamhill nears actual physical implementation, it’s time to start building some more real-time, two-way communication. We’re starting to get some beta testing and discussions going! If you’d like to participate in Project Yamhill chat, please click on the link below. Thank you!

As we approach the dry season here in the Willamette Valley, that signals that it’s time for winter workbench projects to get put on the back burner and our outdoor projects need to be undertaken before it gets too hot in the middle of the summer. As the new owner of a country estate that still needs a lot of development to get it in the state that we desire, that means that my weekends will now be busy with all of this work. I will still be working on Project Yamhill and Etherkit stuff during my remaining weekdays and when I have a little weekend downtime, so I don’t anticipate a huge slowdown in progress, but things will take a little longer during this spring, so I wanted to let you know. A little more on the topic will be presented near the end of this post.

Audio AGC/S-Meter Detector

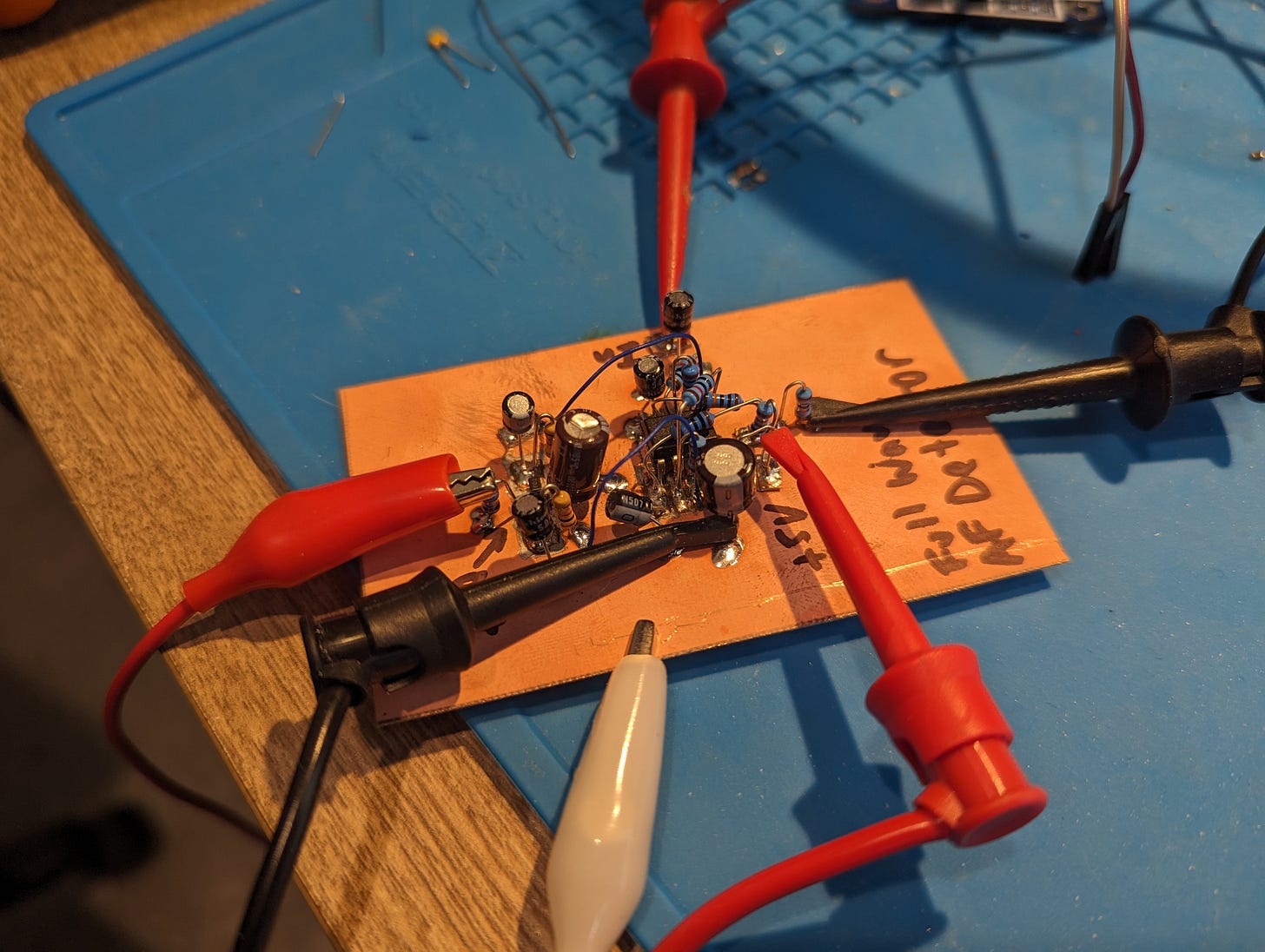

I’ve mentioned in the last few posts in this publication that the one last circuit that I wanted to add to the Rev B Front Panel PCB was an audio detector that could be used for audio-derived AGC and/or an S-meter. I wanted to add a circuit that was relatively simple but bulletproof enough to do the job without many compromises. I don’t have a ton of free real estate on this board, and the board is going to be expensive enough as it is, so I don’t want to balloon the BOM costs any more than I have to.

After doing a bit of online and dead-tree research, I settled on what seems to be a very straightforward and classic design from Solid State Design for the Radio Amateur for a full-wave audio detector circuit that appears to fit my requirements for being simple yet robust enough to work decently.

The above schematic is my tweaked version of the one presented in SSDRA. The concept is simple enough. An initial op-amp stage is used as a buffer/modest gain amplifier used to take the signal from just before the AF gain control and amplify it a bit to give it some good headroom for use with the simple diode detector which follows. The output of the first op-amp is fed to one of a pair of diode detectors (I chose Schottky diodes for their greater sensitivity due to the smaller forward voltage compared to a standard silicon diode). This first stage output also feeds a second, inverting buffer stage which then feeds a second diode detector, thus giving the desired full-wave rectifier action. The original circuit used the venerable 741 op-amp, which I changed to the much better NE5532. I also slightly tweaked the topology and some of the resistor values of the amps in order to meet the needs of Project Yamhill.

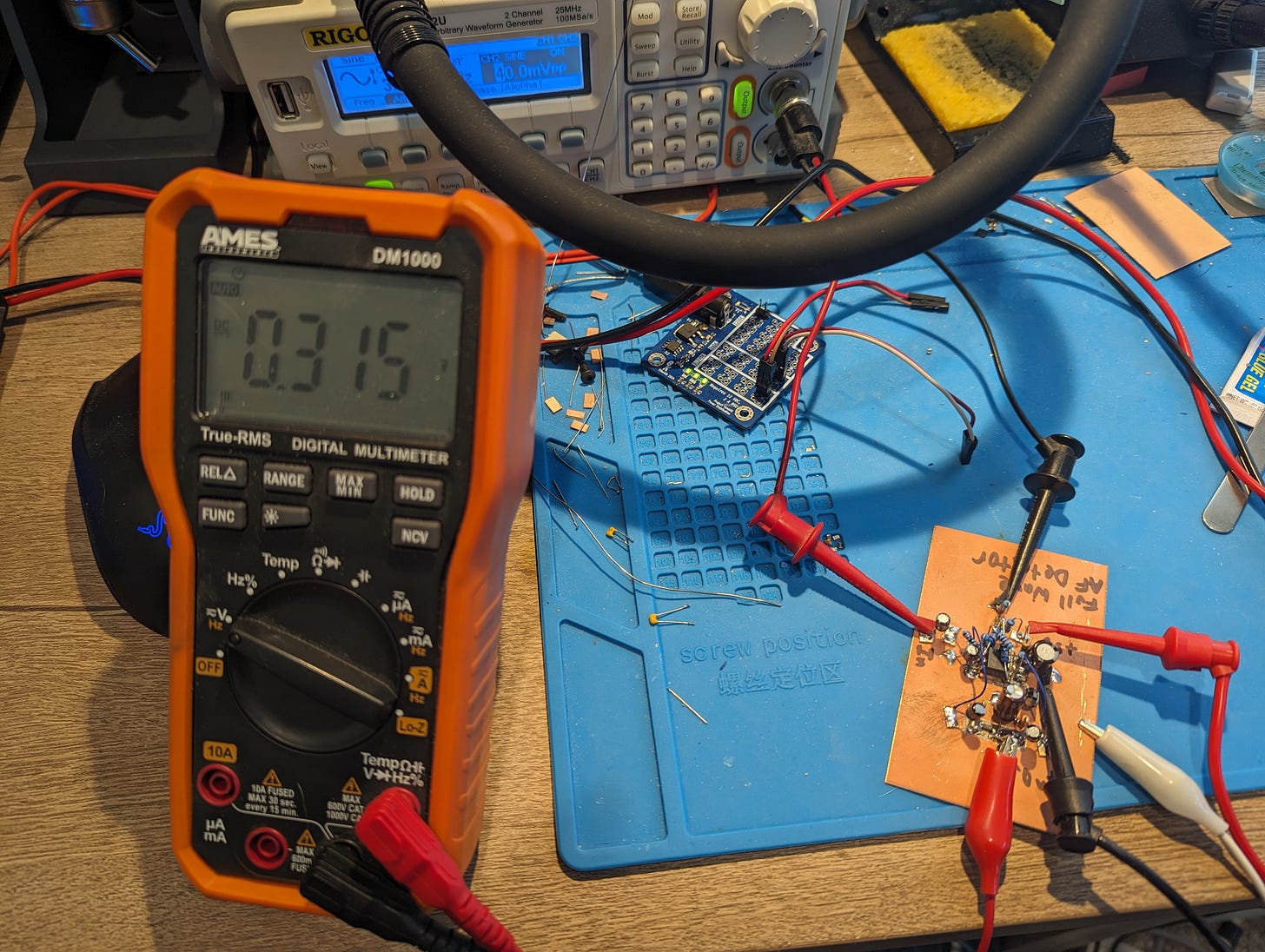

As with pretty much every sub-circuit of the Front Panel PCB, I prefer to actually build and test the circuitry involved before committing it to the design, as board spins are very expensive compared to the other boards in Project Yamhill. Unsurprisingly, the detector did it’s job, and was able to detect an audio signal fed into it starting at about 4 mVpp, and then compressing somewhere around 250 mVpp input (just a rough estimate). That should be a pretty good range, but I can always tweak the gain of the first stage if it’s needed. The DC output signal tops out at around 1.3 V, so I might add a slight gain stage after this to give a bit more dynamic range for the output and to provide further isolation from any detectors which follow.

DC/AF Board Interconnects

Although the old-school 0.1 inch headers that I chose for the DC and AF interconnects are cheap and plentiful, they’re not very robust, not keyed, nor are they easy to line up to connect. I decided to try out the JST-XH connector as a replacement, since they are on the same pin pitch as the Dupont headers, yet are larger connectors overall and are keyed. It was easy enough to order a board connector assortment from Amazon, but when I tried to find some female/female wire assemblies to buy from Amazon, it seems that they don’t carry those. I didn’t realize that wasn’t a common thing. You can get all kinds of wire assemblies with the JST-XH female on one end and tinned leads on the other, but I don’t particularly want to mess with crimping a bunch of wires for when this goes into production.

For now, I’ve acquired a crimping tool so that I can make a handful of cables for prototyping use, but I was a bit worried about how difficult it would be for me to order custom cables. Fortunately, it does appear that there are cable solutions available to small manufacturers such as myself that are very similar to the plethora of PCB manufacturers that now serve our needs.

Priorities

I’ve been plowing full-speed into working on getting Project Yamhill to a state where it can go out for wide testing (other than a few side projects that are still related to the larger goal), however financial realities are forcing me to shift my production priorities a bit. Because so far Project Yamhill has only been a money sink, with the only offsetting income coming from paid subscriptions to this publication (thank you once again, paid subscribers, for your financial support!).

At this point, I realized that I need to step up my income and therefore need to make the relaunch of Etherkit as a retail operation my first priority before I can advance Project Yamhill much further. Getting a web store back up and running won’t be that difficult, but I need to have products to sell. My plan on that front is try to revive my popular Si5351A Breakout Boards. In the past, I was hand-assembling the SMT components on those boards, but frankly that is a ridiculous waste of my time. Instead, I’m going to get some quotes for board assembly for that product, so that all I will have to do is a final packaging step here before mailing those out. Let’s hope that all goes well.

I’ll still need other products for my lineup, so my next priority will be to spin up some of those. I have EtherKeyer Mini nearly ready to go, with just some minor tweaks needed to get it in a good final state. I believe that Party Line 80 is also very close to being ready, however I still need to get some QSOs logged on it first before I do the Rev B board.

What’s Next

With the above priorities shift in mind, my plan is to get the Front Panel Rev B board spin done and in the hopper for my next PCB order, along with Rev B of EtherKeyer Mini and Party Line 80. I will order those at the same time that I order assembled Si5351A Breakout Boards, so getting all of those out the door are still my number one priority.

I was planning on next doing work on my various Etherkit libraries for Arduino, but I think that’s going to have to wait a bit so that I can next work on spinning up the Etherkit as an actual retail business again. That work will happen while I’m waiting for my PCBs to be manufactured and sent back. With any luck, I can have things to sell by the time that summer rolls around, and then I can shift my focus back to getting Project Yamhill into a workable state for a wider beta test.